Sustainable, High-Performance Transfer Solution Redefines Custom Apparel Production

Swonder, a leading innovator in textile printing solutions, proudly announces the official launch of its breakthrough product - DTF (Direct-to-Film) TPU Hot Melt Powder. This cutting-edge adhesive powder sets new industry standards for durability, print quality, and eco-conscious production in digital textile decoration.

Product Overview

Our DTF TPU Hot Melt Powder is a thermoplastic polyurethane-based adhesive specifically engineered for direct-to-film printing applications. Acting as the crucial bonding agent between printed designs and various fabrics, this advanced powder ensures exceptional wash resistance while maintaining fabric breathability. Compatible with both pigment and sublimation inks, it serves as the perfect solution for creating vibrant, long-lasting transfers for fashion, sportswear, and promotional products.

Key Product Features

1. Eco-Friendly Formula

Formulated with REACH-compliant materials, our TPU powder contains 0% phthalates or harmful plasticizers. The water-soluble properties minimize environmental impact during production wash-offs.

2. Superior Adhesion Strength

Achieves 4.5+ rating in ISO 6330 wash tests (40+ cycles), outperforming conventional PVC powders. Bonds effectively with cotton, polyester, blends, and technical fabrics.

3. Low-Temperature Activation

Activates at 130-150°C (266-302°F), reducing energy consumption by 30% compared to standard adhesives while preventing fabric scorching.

4. Optimal Transparency

Leaves no residual traces after heat pressing, preserving original design colors and fine details down to 0.3mm halftone patterns.

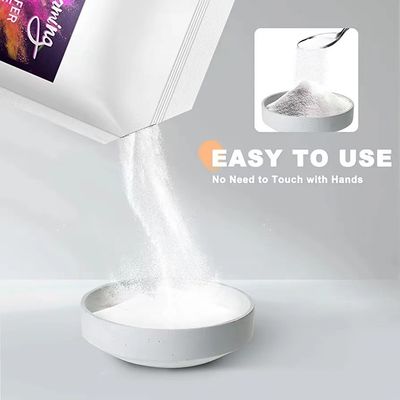

5. Enhanced Production Efficiency

60-second curing time and anti-caking formula enable continuous printing operations. Compatible with all major DTF printer models (Epson, Mutoh, Roland).

Industry Applications

- Fashion Apparel: T-shirts, hoodies, athleisure wear

- Promotional Products: Tote bags, caps, shoes

- Technical Textiles: Medical scrubs, work uniforms

- Custom Design: Photo-realistic transfers for small-batch orders

**Technical Specifications**

| Parameter | Specification |

|-------------------|------------------------|

| Particle Size | 50-120 μm |

| Melting Point | 110-125°C (230-257°F) |

| Activation Temp | 130-150°C (266-302°F) |

| Color | Pure White |

| Shelf Life | 12 months in dry conditions |

| Packaging | 20kg bags with moisture barrier |

Competitive Advantages

Cost Efficiency

Reduces material waste by 40% through precise electrostatic application technology. Enables 1:1 powder-to-design ratio without overspray.

Quality Assurance

Manufactured in ISO 9001-certified facilities with batch-to-batch consistency. Passes OEKO-TEX Standard 100 Class II certification.

Supply Chain Reliability

Available in MOQ of 500kg with JIT delivery options. Supported by 24/7 technical consulting from our DTF application specialists.

Success Stories

Case Study 1

A European sportswear brand achieved 90% reduction in returns by switching to our TPU powder for their yoga wear collections, eliminating cracking issues during stretch tests.

*Client Testimonial*

"Since adopting SW TPU powder, our production speed increased by 25% while maintaining perfect color vibrancy even after 50

industrial washes."

- Marco L., Production Manager, Italian Fashion House

Ordering Information

Available through our global distributor network starting [Month 2023]. Contact our sales team to request free samples and access exclusive

launch offers:

- Email: maggie@heat-transfer-factory.com

- WhatsApp: +86 13110926050

- Website Live Chat: www.dtfprintingmaterials.com

Customized OEM formulations available for bulk orders (50+ tons). Download technical datasheets and application guides from our resource center.

With 15+ years specializing in textile chemicals, we empower printers worldwide with innovative, sustainable solutions. Our R&D center in [Location] continuously develops next-generation products aligned with global eco-standards.

---

Why Choose Our DTF TPU Powder?

Transitioning to DTF technology represents the future of digital textile printing. Unlike traditional screen printing or DTG methods, our TPU powder solution offers:

- 70% lower startup costs than embroidery setups

- Full-color capabilities without plate-making expenses

- Soft-hand feel comparable to direct printing

- Compatibility with dark/light fabrics

- Minimal pretreatment requirements

Environmental Commitment

We actively participate in the ZDHC (Zero Discharge of Hazardous Chemicals) program. All production wastewater is pH-neutral and biodegradable.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!