Product Description:

Material Type

Transparent, coated film designed for use with DTF printing

Printer Type

DTF printer (specialized printer with CMYK inks and white ink for opacity).

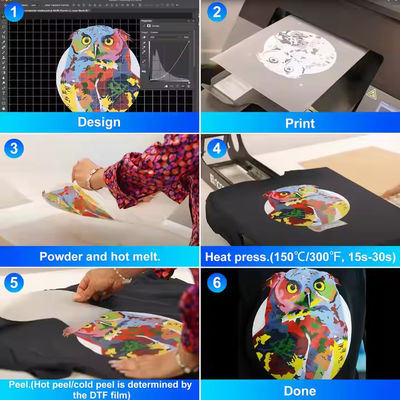

Design Printing

Designs are printed in reverse (mirror image) onto the film with CMYK and white ink layers.

Adhesive Powder

A special adhesive powder is applied to the printed design while the ink is still wet.

Roll Size:

30/33/60cm*100m / Custom Size

Samples:

Available(free Sample)

Heat Press Temperature

Recommended temperature: 320-356°F (160-180°C). Press time: 10-15 seconds at medium pressure.

Sheet Size:

A3/A4/A3+/Custom Size

Peel Method:

Hot Peel/Warm Peel/Cold Peel

Product Thickness:

75 micron/100 micron

Type:

Single Side/Double Side

Storage

Store in a dry, cool place to maintain film quality and prevent moisture damage.

Applications:

Applications:

DTF film is widely used for printing custom designs on T-shirts, hoodies, sweatshirts, hats, and other garments. It works well on cotton, polyester, and blends.Great for printing on sports jerseys, workout gear, and performance wear. The flexible and durable prints can withstand regular movement and stretching.

Key Benefits in Various Applications:

- Flexibility: Works on a wide range of materials (cotton, polyester, blends, and even non-textiles like wood and ceramic).

- Durability: The prints are long-lasting, with good resistance to washing and wear, making them perfect for apparel and items subject to frequent use.

- Soft Feel: DTF prints have a soft and flexible feel on fabric, unlike some other transfer methods that can be stiff.

- Cost-Effective: Ideal for both small runs and mass production, making it accessible for businesses of all sizes.

Packing and Shipping:

When packing and shipping DTF transfer films, the goal is to ensure the films arrive safely and undamaged, especially since the material is sensitive to moisture and physical handling. Here’s a breakdown of how DTF film is typically packed and shipped:

Packing Process

-

Protection Against Damage: DTF transfer films are usually rolled onto a sturdy cardboard core. This prevents creasing, which could affect the quality of the film when printing. The rolled film is then often wrapped in bubble wrap or foam sheets for added protection against physical damage like bending or crushing during transit.

-

Plastic Bag or Film: To protect the film from moisture, it’s common to wrap it in a plastic bag or cover it with moisture-proof material. This ensures that no environmental factors, such as humidity, affect the film’s quality during shipping.

-

Outer Packaging: After the film is rolled and protected, it's usually placed in a corrugated cardboard box or a sturdy cardboard tube, especially if shipping in a roll. These materials provide a secure outer layer that safeguards the contents against impact and ensures the film doesn’t bend or get damaged during transit. For flat shipments (less common), the film would be placed in a padded envelope or flat box.

-

Sealing: The packaging is sealed securely, and fragile or handle with care stickers might be added to ensure that the box is treated gently. Packing slips or invoices are typically included inside for order verification.

Shipping Process

-

Shipping Carrier: DTF films are typically shipped using well-known logistics companies such as FedEx, UPS, DHL, or USPS. For local deliveries, standard ground shipping is often sufficient, while expedited options can be chosen for faster delivery. International orders might require air freight or express services for quicker shipping.

-

Tracking: Once shipped, a tracking number is provided to the recipient. This allows them to monitor the progress of the shipment and estimate the delivery time.

-

Delivery Time: Shipping times vary depending on the location. Domestic shipping usually takes around 3-7 business days, while international shipments can range from 7-21 days or more, depending on the destination and the shipping method.

-

International Shipping Considerations: For international orders, customs duties, taxes, and other fees might apply. It’s important to include the necessary customs documentation (such as commercial invoices or customs forms) for smooth processing at the border.

Special Considerations for DTF Film Shipping:

-

Humidity and Temperature: DTF films should be kept in dry conditions to prevent moisture absorption, which could affect the print quality. Also, exposure to extreme temperatures during shipping can cause damage. Hence, it’s important that the packaging is resistant to environmental fluctuations during transport.

-

Bulk Orders: For larger orders or bulk shipments, pallet shipping might be used. The films are securely wrapped and protected on pallets to ensure that they are not damaged by heavier items.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!